Enhanced WWTP nitrification with OxyMem™ MABR

Faster, stronger, harder…

OxyMem™ MABR (Membrane Aerated Biofilm Reactor) is a unique biofilm system that can be used to intensify existing wastewater treatment facilities. A microbial film is established on millions of tiny gas-permeable membranes. This biofilm breaks down wastewater pollutants effectively with highly efficient oxygen transfer. Ammonia removal can be enhanced with every additional OxyMem™ unit added.

OxyMem™ MABR offers wastewater treatment process intensification thanks to:

- Faster deployment and retrofit. Just drop in MABR into your existing facility.

- Stronger process – process intensification with bubbles aeration and therefore significant increase of biomass in a short amount of time. More resilient biomass grown as a biofilm.

- Harder, more resilient to increased loading rates, and faster pollutant removal even in difficult-to-treat wastewater. Enhanced ammonia removal.

Watch short video explaining Enhanced Ammonia Removal

FASTER DEPLOYMENT and RETROFIT

Drop in a Modular MABR unit (module) into your existing Plant

OxyMem™ MABR modules have been designed with transport and installation in mind. Shape, size and lifting arrangements allow for easy deployment. See designed-in features.

- There is no preparation involving civil engineering work needed. You can use your existing wastewater treatment infrastructure like aeration basin.

- You do not need to drain the tank. You can simply drop in module or multiple modules without interfering with the ongoing processes.

STRONGER. PROCESS INTENSIFICATION

Significant increase of biomass in short amount of time

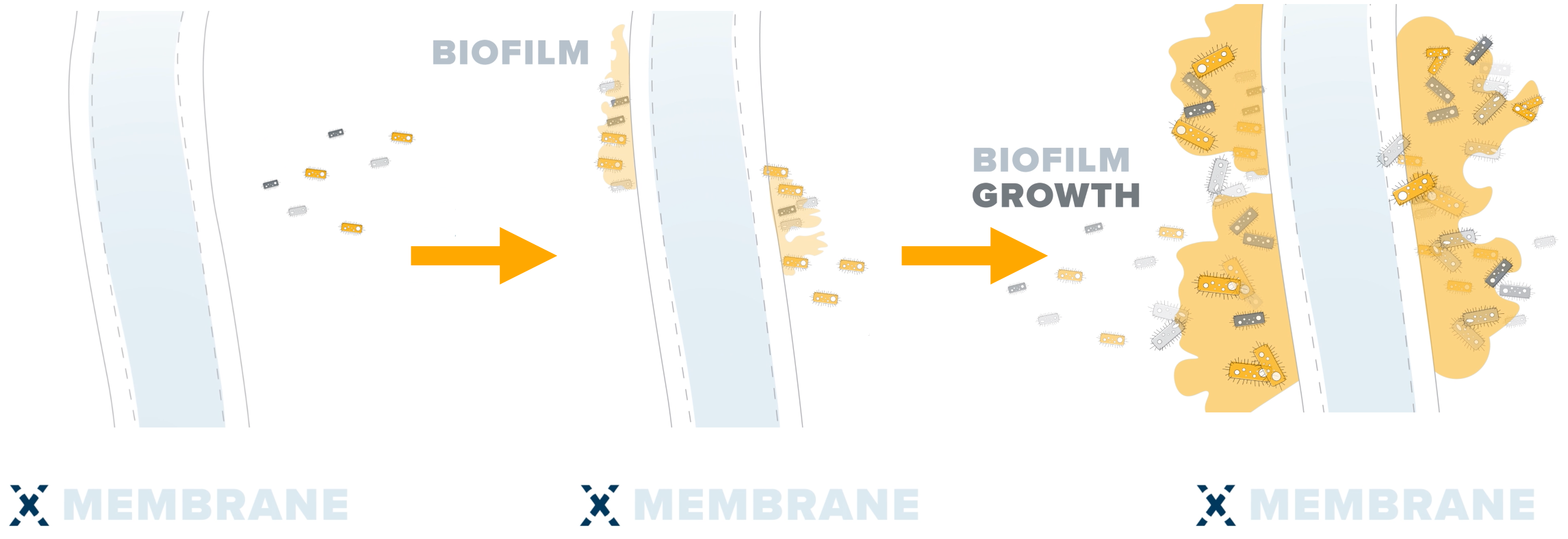

Every module of OxyMem™ MABR contains oxygen permeable hollow membranes.

Wastewater treating microbes grow on the outer surface of the membrane as fixed to it film – biofilm. The oxygen transfer rate is very high here as the oxygen coming from the inside to the outside of the membrane delivers oxygen directly to biofilm, no bubbles, with very little losses. It is called a bubbles aeration. Huge improvement in the mass transfer rates from both sides of biofilm grown on the OxyMem™ membrane is a result of the OxyMem™ MABR unique design.

Biofilm grows much faster than planktonic cells and forms much more resilient culture immersed in the carbon source pollutant-rich wastewater. Thus, more robust biological wastewater treatment is achieved in shorter amount of time by this immobilized culture. Only within few days from OxyMem™ MABR deployment ore biomass grown as a biofilm can be observed. Read more here.

HARDER. ENHANCED AMMONIA REMOVAL

Faster pollutant removal even in difficult wastewater

Ammonia is becoming increasingly a problematic wastewater element.

OxyMem™ MABR delivers enhanced ammonia removal as it facilitates simultaneous nitrification and denitrification. Biofilm grown in the MABR system is a robust and fast-growing mixed culture of cells with different nutrient as well as oxygen concentrations needs. The oxygen delivered from the membrane side penetrates biofilm with different rates creating species stratification, and that allows a unique relay of microbial activity.

Contact us to learn more about other OxyMem™ MABR benefits and how it can work for your wastewater treatment plant.