Chemical Oxygen Demand (COD) is a critical metric used for testing the effectiveness of the wastewater treatment. The test is used by the industry as it can be carried out in a couple of hours unlike the BOD test which can take 5 days.

If the COD result is high it can indicate that there are issues with the wastewater treatment.

The higher the level of COD the more polluted the water is.

If wastewater treatment plants do not reduce the organic matter from the wastewater before it is discharged, it can have damaging effect on the receiving waters as it can consume the oxygen in the water and harm the fish and ecosystem.

Chemical Oxygen Demand (COD) is a measures the total organic matter in the wastewater. It includes both the biodegradable and non-biodegradable matter.

It is expressed in mass of oxygen consumed over volume of solution which in SI units is milligrams per litre (mg/L).

Biochemical Oxygen Demand (BOD) measures only the biodegradable matter in the wastewater. Chemical Oxygen demand is always a higher result.

Unlike conventional systems that use bubbles MABR use's hollow tubes to deliver oxygen directly to bacteria growing on the membranes. Conventional systems need lots of pressure to get air through the water to the suspended biology. This process is energy intensive and causes over 70% of the oxygen to never reach the bacteria that requires it to grow.

In the presence of oxygen, ammonia is converted to nitrate and the COD is either consumed for denitrification or oxidised by the bacteria

MABR uses a special material that allows molecular diffusion to occur. This chemical reaction means oxygen passes through the walls, directly to the biofilm, without the risks of compromising strength or clogging.

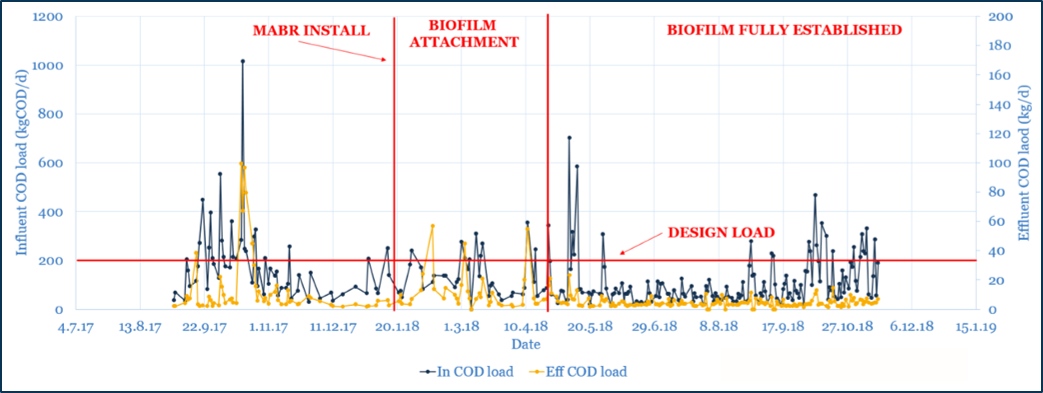

The client was operating in an industry that suffered from seasonal increases which were putting stress on the plant . The primary objective for the plant was to increase biological treatment capacity and ensure consistent regulatory compliance on discharge during peak seasons, without taking the plant offline or stopping the existing process.

After the installation of the OxyMem OxyFAS modules and an initial growth phase of approximately two months for the establishment of the biofilm. The client’s effluent quality has stabilized, the effluent load rarely exceeding 10 kg COD/d.

During peak season the average daily effluent load from decreased from 19 kg COD prior to installation to below 5 kg COD/d after the install.

The stability of the effluent COD load was excellent during this period despite the wide variation of the influent load.

Click the link below if you would like to learn more about how MABR can help you increase the biological capacity of you plant.

© Copyright 2017-19, OxyMem Limited | Company Registration No. 530400 | VAT Registration No. IE3192612NH | INBS