Many of the worlds wastewater treatment plants are aging and struggling to cope with the current demands placed on them. They were designed and built to meet the needs of a different time, when there were smaller populations, less industrial demands and less regulatory controls. Now these same wastewater plants are now faced with the reality that they need to an upgrade their facilities to meet current demands and effluent quality controls.

Expansion via traditional methods can take up a company’s valuable resources and create logistical challenges for a company, however finding an alternative way of expanding such as MABR can offer some real benefits and can make the process more achievable.

Using OxyMem’s MABR as means of expanding will have significant benefits for a company. MABR can also address some of the challenges of expanding. It will allow treatment plants to increase their biological capacity and improve effluent quality to future-proof their plant in a much faster time and without the need to increase their footprint.

Access to Land

In order to upgrade their facilities in a traditional way a company will need to have access to land for expansion. If they do not already have the land required, they will need to purchase it, this can be both an expensive process or an immediate challenge as the land may not be available.

Due to current population growth rates and the re-zoning of land for residential and amenity use the available of land is scarce in some regions.

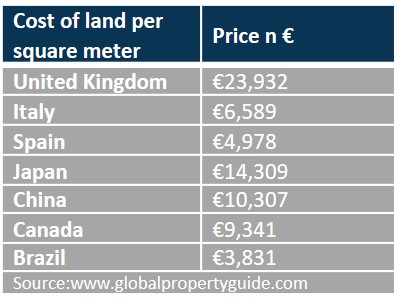

As well as becoming scarce, the cost of land is also increasing and this can make expanding an expensive investment. According to the Global Property Guide the price of land per square meter can vary across the world.

When companies upgrade their facilities using OxyMem MABR modules they do not need any additional land. Our modules can be retrofitted within a existing wastewater treatment plant of almost any size often without emptying the tank. This means that to upgrade there is no need to purchase additional land or build new infrastructure which can be both difficult to access and can be a costly process. Alternately our MABR modules can also be used in new builds to help deliver increased biological capacity and to future proof the facility to meet its demands.

Ease of Installation

Even when companies have the required land, there are still several challenges to overcome. In order to build the required infrastructure companies will need to obtain planning permission and allow the time necessary for the infrastructure to be built. This can be a long process that may take years. It can also put pressure on the current infrastructure and processes.

Will current processes need to be stopped?

How will the new and old system be connected?

The cost of building the infrastructure is another challenge; According to the International Construction Market Survey 2018 by Turner and Townsend global constructions cost are set to rise in the coming years. In 2018 there was an expected increase of 4.3 percent following a 4.1 percent rise in 2017.

The increase in the global market is expected to impact most countries, as within the report it stated that 21 of the 46 markets measured are expected to warm up in 2018, just two are expected to cool.

OxyMem’s MABR modules help overcome these challenges as our modules are quick and easy to install. The modules can be dropped into the tanks without the need to stop production or drain your tank. The installation process only takes a couple of days.

To learn more about how MABR can help you future-proof your facility contact us today.

© Copyright 2017-19, OxyMem Limited | Company Registration No. 530400 | VAT Registration No. IE3192612NH | INBS