OxyMem MABR enhances process stability and robustness

Increasing populations, industrial growth and tightening environmental standards continue to challenge existing wastewater treatment plants (WWTPs) as they operate close to and often beyond their design limits. Many of the world's existing wastewater treatment plants need upgrading; due to treatment capacity issues or regulatory targets. Upgrades are now longer choice but a necessity for environmental compliance. These existing treatment plants can face several challenges when it comes to upgrading.

In this "Pain" series, we will look at some of the critical challenges wastewater treatment plants face when it comes to upgrading their facilities.

Challenge 4: A Robust Environment

Plant owners and operators need to have the confidence that their effluent will be within consent all year round. An unstable process is usually difficult and time consuming to operate and can develop both operational challenges and environmental risks. Having a robust, stable treatment system in place is critical for consistent success and peace of mind.

OxyMem MABR attached-growth biomass is easier to retain and manage within a biological tank, when compared to traditional ASP plants with a suspended biomass that needs to be kept in suspension, well mixed and controlled (eg. sludge wasting). MABR nitrifiers are easily maintained for consistent treatment throughout the year, offering a more stable and reliable process.

OxyMem offers the market the most advanced attached-growth biofilm system available today. The OxyMem MABR habitat creates an ideal environment to support a biofilm which absorbs and consumes carbon and nitrogen-based pollutants. This MABR biofilm is not like that found on other attached growth systems such as IFAS or MBBR.

MABR offers impressive process resilience.

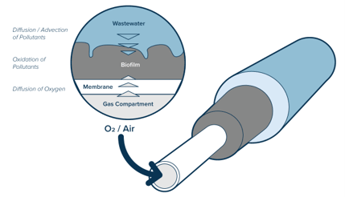

Alternate attached growth systems receive the oxygen they required from bubbles, meaning their aerobic biofilm layer is the outermost layer (ie. on the water side, close to the bubbles and furthest from the media). These outer biofilm layers are subject to daily process fluctuations and are susceptible to toxins, chemical spikes, abrasion and washout (eg floods). In these instances the performance of important aerobic bacteria can easily be affected and so the stability of the overall treatment process. Note, if important biomass is removed or damaged, it can take considerable time to grow back again (eg. during winter months when metabolism is slower); treatment capacity remains reduced until healthy biomass increases.

MABR is not as susceptible to process upsets. With the aerobic bacteria as the innermost layer, well attached to the media (oxygen diffuses through the membrane fibres on a molecular level), the important aerobic layer is better protected.

With oxygen readily available and a protected aerobic biofilm layer, the MABR system is not as susceptible to process upsets (surface abrasion, washout or harmful chemicals) that may damage or kill the aerobic layers on typical MBBR or IFAS systems. The result is a very robust aerobic system and a more stable treatment process.

OxyMem MABR offers treatment plant owners and operators a high performing, stable and robust biological treatment process; confidence that effluent will remain optimum and consistent, with fewer operational challenges and less risk of negative environmental impacts.

Contact us today to learn more about MABR.