Making Your Wastewater Treatment

Plant More Efficient

Wastewater Treatment plants are not usually the source of innovation - with many continuing to operate much as they did a few decades ago. However, you may have heard of some recent successes due to the commercial application of an innovative approach to treatment - using Membrane Aerated Biofilm Reactor (MABR) technologies.

This solution is gaining a lot of attention around the world due to the quantified benefits that combine to improve overall operational efficiency.

These benefits include significant improvements in energy efficiency, and reductions in tank footprint, in sludge production and in operator support time.

Simply installing a number of MABR modules in an existing tank enhances treatment performance, and provides additional process capacity overnight.

Key Benefits Include:

- 75% Energy Saving

- 50-80% Tank Savings

- 50% More Capacity

So how do you explore whether you should be considering OxyMem for driving efficiencies at your plant?

The following 3 step process will help you quickly evaluate whether this area warrants further exploration.

Step 1 Understand What an OxyMem MABR is and What it Does?

Knowing how the MABR works helps you understand what it is, what it does and how it may fit into your wastewater treatment process?

Is it a highly efficient aeration system? Would you like to increase the load treatment capacity or improve the effluent quality of your current aeration basin, your sequencing batch reactor (SBR) tank or even your MBBR without upgrading your blowers or without even entering the wastewater tank?

And when it comes to installation all you need is a crane and a few days to get it up and running.

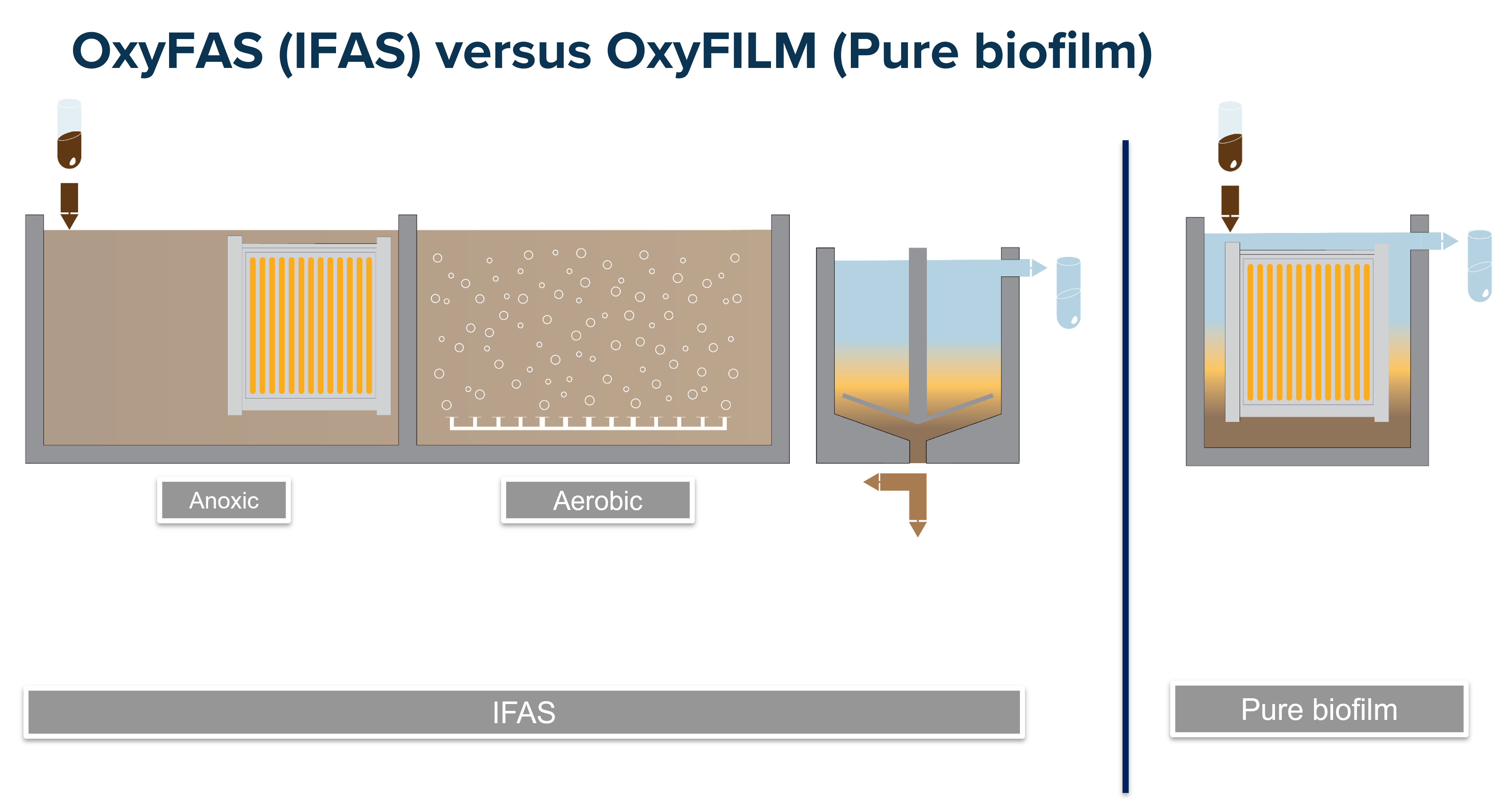

Is it an advanced MBBR or advanced IFAS? Any process currently making use of an attached growth (fixed biofilm) media could be supercharged with OxyMem’s aerated media. Instead of inert, oxygen deprived plastic media being mixed in a bed of aerated wastewater, attempting to find oxygen for treatment, inefficiently, the OxyMem MABR media delivers oxygen directly to where it is required - the media surface. Oxygen is delivered directly to the biofilm itself. This supercharge is equivalent to an athlete performing in an oxygen rich environment as opposed to an oxygen deprived environment. Performance is enhanced, naturally.

Is it a means of reducing your sludge production? One characteristic of the OxyMem system, an attached growth biofilm system, is its long sludge age. Longer sludge age systems produce less sludge than conventional activated sludge plants, thus requiring less pumping, storage volume, dewatering, transportation and disposal. Our environment benefits from less tankers being on the road.

Step 2 Understand The Key Benefits

Input values into OxyMem’s easy to use online Design Tool to help you assess the potential tank volume you may require, the efficiency of running an MABR and the volume of sludge you may expect to produce. The results of this basic tool will enable you to compare the ongoing OPEX costs of MABR against any alternative treatment you are considering. Be sure to consider all the benefits offered, even the hidden ones such as savings on land procurement, sludge storage vessels and disposal costs, and the fact that blowers and a blower building may not be required at all on your site.

Step 3 Sign Up for a Trial

OxyMem offer a number of entry level trial options which will demonstrate the power of the MABR application on your existing municipal or industrial process wastewater. Having run a pilot test and gained confidence in the MABR technology first hand, clients are then able to scale up to larger plants with ease, and with the knowledge that their advanced technology system will be brought online and meet effluent consents with minimal process and minimal financial risk.

Summary

MABR can be dropped into legacy tanks, where available, to deliver additional treatment capacity (IFAS style) without interfering with the current treatment process. Up to 50% additional capacity may be obtained within a matter of days, offering all of the MABR benefits noted above. Why not see the benefits yourself with our entry level solutions?