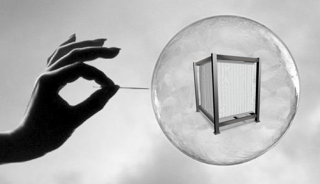

Innovate or Die.....Wastewater Treatment With Bubble-Less Aeration

Why OxyMem is Shaking up the Wastewater Treatment Industry?

Since taking on my most recent role as Commercial Director at OxyMem various people have already asked me questions such as;

“Why would you leave the position you had with a reputable, established aeration manufacturer, within the world of fine bubble diffused aeration, to go work for a small Irish firm that’s only a few years old and selling something the world hasn’t seen yet?”

The frequency of these types of questions certainly make me very aware that I am doing something different or something seen as risky to most, especially when the question comes from respected colleagues within the water industry. Though aware, I have never been known to simply stay with the status quo, so I give my response without hesitation.

“Because sometimes, just sometimes, that one great thing comes along, and your gut tells you that you would be foolish to miss an opportunity to be part of it.”

Extensive Career in Wastewater

My career in wastewater started approximately 20 years ago, when I was appointed by Sanitaire (Xylem) to design and size pumps, pump stations and preliminary treatment facilities on treatment plants. This progressed to site based activities; installation and commissioning of equipment and managing teams on site; primarily on aeration projects. My familiarity with aeration products and the intricacies of various manufacturers helped springboard me into the world of Sales, Sales Management and Global Sales Director. I know I have been extremely privileged to have worked with some of the largest aeration manufacturers on the globe, and to be personal friends with people of amazing talent within the world of wastewater aeration. You can see how them questioning the next step in my career may have made me sit up and think a little.

My Introduction to OxyMem

I was introduced to Wayne Byrne, CEO of OxyMem, at WEFTEC in the USA a few years back, and we had a pleasant but brief chat at his booth. Now that I think of it, it wasn’t even a booth, more like a stand, furnished only with a single chair (no table… no room for this) and a small bench-top test unit measuring only approximately 2’ tall.

What Wayne described with his first few sentences during that meeting had me in total awe. I approached him as someone who thought they knew everything there was to know about the latest developments in efficient oxygen transfer into wastewater, using fine bubble diffusers. Once he had finished his sale’s pitch, (and I know it was a sales pitch … I am in Sales), I voiced, “If that can do what you just said it can do, it will drastically change the world as I know it and others know it”.

I was being serious; if the tiny batches of thin-wall hollow membranes in front of me could allow oxygen to be transferred to the wastewater with a back pressure just over atmospheric, using a small blower, pulling negligible power, would not clog - because there are no holes in the membrane to clog, and produced half the sludge as a traditional activated sludge treatment system, then I stood to be in trouble, soon. At that moment it seemed we were on the brink of entering the MABR era (Membrane Aerated Biofilm Reactor). How could we not be? It was logical.

MABR Comes of Age

I was well aware that my world would not change overnight, just as the first “brick” mobile phones and green screened DOS computers held their ground for a time as the market and technology advanced, but for me the writing was clear on the wall. We are all living in a world where people demand smaller, faster, easier, cheaper… and modern. It was only a matter of time before this bench-scale unit would prove itself to the industry and I knew if OxyMem could get it to a point where it was economically viable, I wanted to be part of it. Part of the future.

Two years have passed since that fateful encounter at WEFTEC. I have followed OxyMem’s blogs and watched them pick up almost every award going for innovation, start up and energy savings. I then discovered that large players in the wastewater treatment industry such as Severn Trent Water, Kurita, Xylem, and Agbar had been testing OxyMem MABR for years and that apparently they were liking the results.

If this company was David in the well-known David and Goliath story, then the Goliath would have to be GE, for GE were also chasing the MABR world and investing heavily. Again, clearly, it’s where the industry was going and we all know you cannot stop evolution. Surely they couldn’t be wrong ….?

DOW Invests in OxyMem

As it turns out I was not the only one watching OxyMem closely; The DOW Chemical Company were in discussion with OxyMem and also had an MABR on trial for years, as have Suez. It seems everyone wants proof, it’s a human trait. DOW (another Goliath) liked the product so much they stepped forward into the limelight to stand alongside this little start-up Irish company. They finally decided to invest in the company during the first quarter of 2016 and have become OxyMem’s first strategic business partner in Brazil.

It was at this time that I was approached by Mr Byrne, who reminded me of what I had said two years before at that small OxyMem booth in America. “Do you still want to be in on it?, Do you still believe this product is a game changer?”. I did, I do, and that’s why I now find myself among the team here at OxyMem.

Wastewater Aeration Innovation

This product will change wastewater aeration as we know it. Ceramics had their day (but still have a place of course), discs are making way for panels where energy is the driver, rubbers are being changed out for advanced polymers and in time this bubble-less MABR technology will get its hold on the market. It is, in my opinion, the most advanced and most efficient means of transferring oxygen to wastewater on the planet today, and OxyMem are the first company to have commercialised it, to have signed an agreement with an A-list global manufacturer ensuring ease of worldwide distribution, to have The DOW Chemical Company behind them and perhaps most importantly to owners and operators, to have tested it extensively to the point where they comfortably offer a standard 10 year membrane warranty alongside performance or effluent guarantees, if required.

This is my short story and one that I will no doubt tell for a few years to come. I do not have a crystal ball (if I did I might have been on my own island by now!), but I know enough about the wastewater and aeration market, and have heard enough experienced aeration engineers’ views to know this technology is set to be the next paradigm shift in the aeration market. It is indeed a “game changer” and will be disruptive to the world as we know it.

“Because sometimes, just sometimes, that one great thing comes along, and your gut tells you that you would be foolish to miss an opportunity to be part of it.”

John McConomy is the Commercial Director of OxyMem