Advantages of OxyMem MABR over standard attached growth systems

OxyMem solves OPEX intensive wastewater treatment with an innovative ‘Drop in’ solution for wastewater treatment.

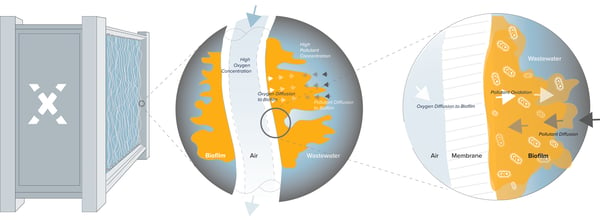

Easily deployed OxyMem modules provide wastewater treatment plants with the simplest means of increasing their plant treatment capacity and effluent quality. Our patented bubble-less transfer of oxygen emulates a natural respiratory system, providing highly efficient oxygen transfer and provides simultaneous nitrification and denitrification for total nitrogen removal.

Save on energy, reduce waste sludge and decrease your upgraded plant's carbon footprint when compared to traditional biological systems, with no additional infrastructure and no plant downtime.

The OxyMem MABR technology offers several advantages over standard attached growth systems. Below are just some of the

key benefits.

Ease of Installation

Self-contained, modular “drop-in” units allow easy upgrade of your existing treatment plant. Conventional attached growth treatment systems often require tanks to be emptied and cleaned prior to installation. Aeration diffusers, mechanical mixers, sieves and screens to retain standard media are often need to be put in place with standard attached growth systems.

OxyMem MABR modules do not require tank draining, diffusers, sieves or additional mixing.

Modular Plant Expansion

If a plant needs only a few additional mg/l of a pollutant to be removed, OxyMem can deploy the correct number of modules to target this; and add additional modules only when necessary (perhaps in another 5-10 years). There is no need to change a plant today to meet a process load that will not be realised for another 10-20 years (if ever).

Existing Process Can Remain in Place

Note: There is no process risk when deploying OxyMem for additional capacity, as we do not change our client's process; ie. if a client has a CAS system today, they will have the same CAS system tomorrow, .... with a few MABR units strategically installed also. OxyMem modules can be removed again, at will. No negative impact will be experienced, where other attached growth upgrades may require a disruptive process change.

Advanced IFAS Media

OxyMem manufactures the most advanced attached-growth media available today. Biology (biofilm) becomes established on the outer surface of precision engineered, gas permeable, micro-bore tubes (OxyMem MABR membrane), and it obtains the oxygen it requires directly across the membrane wall; ie. No additional diffusers or aerators are required to provide oxygen to the system. Gases entering and leaving each MABR module can be easily monitored in real time to measure oxygen transfer etc.

Enhanced Performance

The advanced silicone, gas permeable hollow fibres (membrane tubes) have been designed with a geometry, wall thickness and rigidity that provides maximum air distribution throughout the whole MABR module.

OxyMem design their membrane fibres to provide maximum available surface area and to improve biofilm-pollutant contact during operation; enhancing performance during operation.

Biofilm Thickness Control

The thickness of the biofilm on an OxyMem MABR membrane can be assessed and optimised to ensure best performance.

Varying the layers of biofilm using an aggressive scour, on demand, helps ensure Carbon, Ammonia or TN targets are achieved.

Standard IFAS/MBBR systems cannot control the biofilm thickness on demand and the performance cannot therefore be adjusted, controlled or enhanced by operators on site to target specific pollutants.

Robust, Aerobic Bacteria

The innermost aerobic layer of the OxyMem MABR biofilm is protected under the outer layers. Chemicals or troublesome toxins that may find their way into the bulk liquid will therefore not damage or kill the aerobic (inner) layer first. The result is a very robust aerobic system.

Standard attached growth systems have the aerobic layer as the outermost layer and these outermost layers may easily be affected by slight changes in the wastewater chemistry, affecting process performance easily and significantly.

Energy for Aeration

OxyMem membranes transfer oxygen directly to the attached biofilm just as the human body distributes oxygen to every living cell – through molecular diffusion. With no alpha factor to consider, OxyMem offers the most efficient means of transferring oxygen to a biofilm and thus significantly minimises energy consumption. Actual Aeration Efficiencies of ~15kgO2/kWhr could be realised where conventional aeration may deliver 2kgO2/kWhr.

Standard IFAS/MBBR systems rely on bubbles to deliver oxygen. Bubble aeration has been seen as the most efficient means of transferring gases within wastewater for the past 100 years. The latest MABR technology is changing this norm, given our need to reduce energy consumption and help our environment on a global scale.