Full scale OxyMem™ MABR deployment at Elmira, Canada

The Region of Waterloo is a municipality in eastern Canada that has been a leading advocate for the adoption of MABR. The Region has separately trialed technology from two MABR vendors at two wastewater water treatment plants. This second full-scale commercial MABR deployment, following a one-year trial of OxyMem™ OxyFILM™ modules, demonstrates the municipality’s growing confidence in this latest technology.

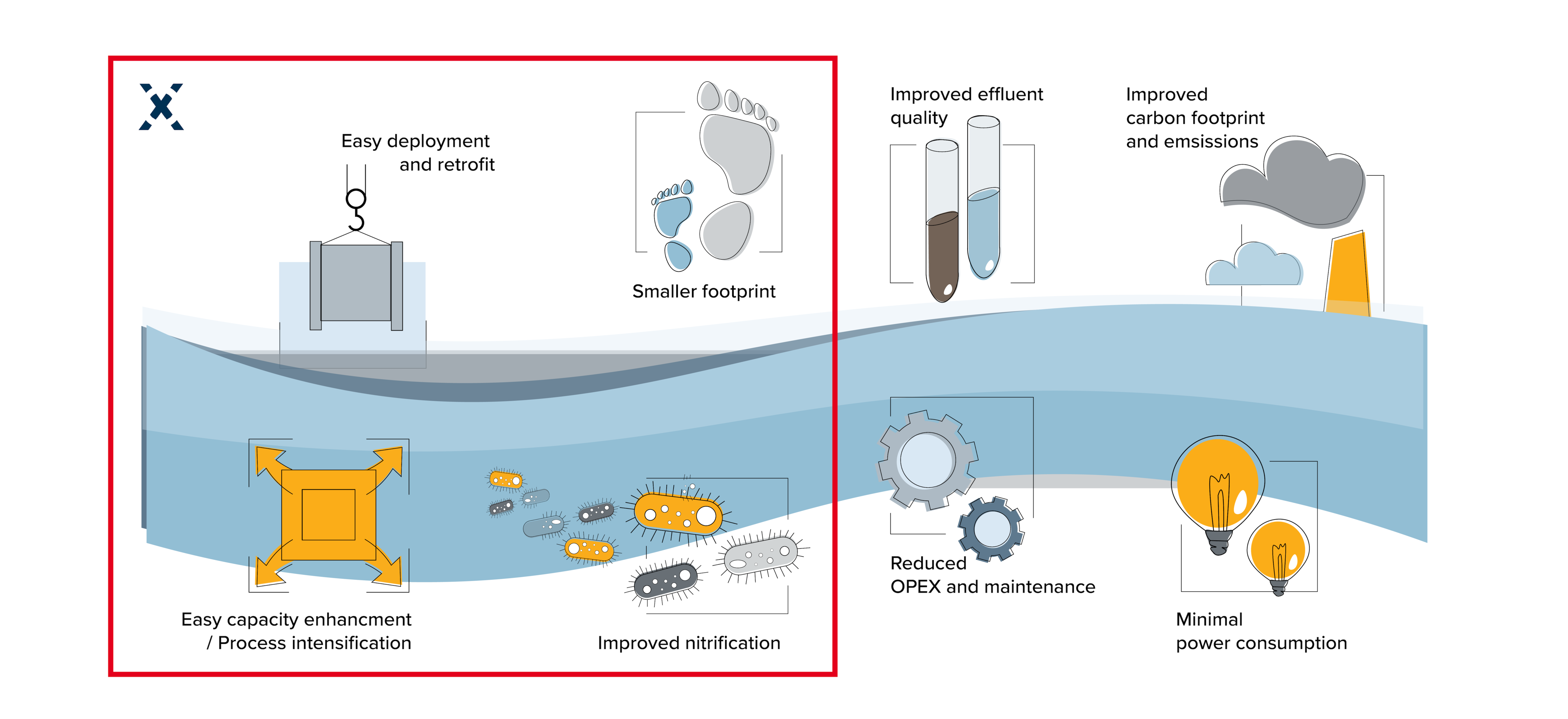

Full-scale DuPont™ OxyMem™ MABR deployment was chosen to be installed at the Elmira wastewater treatment plant in Canada by the Region of Waterloo. The OxyMem™ MABR system allows for expanded treatment capacity through process intensification, without the need to expand the operational footprint of the plant. Making use of existing infrastructure and being easily deployed, usually without disrupting treatment processes, OxyMem™ MABR modules can be a drop-in, plug-and-play upgrade solution.

The first full-scale commercial installation of OxyMem™ MABR modules in Canada is expanding the capacity of the Elmira wastewater treatment plant within the Region of Waterloo, which has a design flow of 7800m3 per day.

Frequent high industrial and seasonal flows and loads at Elmira highlighted that capacity enhancement was essential for the future smooth running of the plant. The MABR modules were installed within reactors one and two on site to bolster the current process and help futureproof beyond 2040. Additional nitrification capacity is provided via the MABR attached growth biofilm.

One of the key reasons for specifying MABR was the lack of available space to accommodate the building of additional biological treatment tanks at the facility. OxyMem™ MABR modules could be placed directly into the existing tanks, enabling the municipality to increase capacity without expanding the plant’s operational footprint.

Eight OxyMem™ MABR modules, supplied through local representatives Aquafy, provide process intensification and additional biological treatment capacity. The modular system is incredibly flexible. Given the size of the existing biological tanks on site, significant further expansion using MABR is possible should additional treatment capacity be required at the plant in the future.

As a site inspector, I am the eyes on the ground for both the end client and our consultant, working hand in hand with contractors to ensure that construction goals are captured within our design. The deployment at Elmira faced some unique challenges that we were able to overcome in collaboration with the OxyMem team, who were quick to respond to our queries. Aging existing infrastructure and changes in the hydraulic profile were mere speedbumps on the road to success as we worked together to ensure we achieved our objectives.

– Jesus Flores, Site Inspector, Jacobs

OxyMem™ MABR technology is an innovative plug-and-play solution. After placing modules into the existing tank infrastructure, you simply attach the small air blowers and turn them on. Each module begins to work the instant after it is dropped into a working wastewater treatment plant. Every individual module installed adds treatment capacity.

Deployment is incredibly simple. The modules arrived accompanied by a semi-automatic lifting rig that lifts each module and automatically locks it into position. After flying it over the tank and setting it down, there is no need for someone to enter the water to disconnect it; the rig automatically disconnects itself, allowing it to be lifted out by the crane.

The system is made plug-and-play thanks to quick and easy connections between the modules and the air piping system. Rubber hoses and cam locks save time while providing a reliable connection and eliminating any concerns about vibration.

My responsibilities included the installation of the MABR system. This was a straightforward system to install. Everything bolts together. The quality was excellent. The drawings were very well laid out.

– Paul Korczynski, Lead Site Supervisor, H2Ontario

© Copyright 2017-19, OxyMem Limited | Company Registration No. 530400 | VAT Registration No. IE3192612NH | INBS